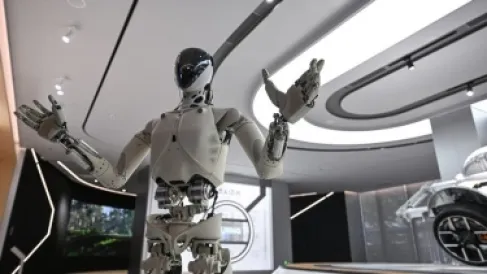

Khaberni - It appears that providing robots with a hand capable of functioning in a manner similar to the human hand remains an elusive goal for robotics companies at this time, as achieving it is still far out of reach.

Rich Walker fondly remembers the first robotic hand that Shadow Robot Company created in the late 1990s, which was made of wood, springs, and rubber bands.

Walker, who now holds a managerial position in the company, said: "Much of it was made using what was only available to us at the time."

At Shadow Robot's headquarters in North London, the robotic hands were small cylindrical arms containing electric motors known as actuators, which pulled on metal strings to move the fingers accurately, according to a report by the British Broadcasting Corporation (BBC), reviewed by "Alarabiya Business".

To operate these robotic hands, sensors are attached to the user's fingers and some basic instructions are given. These hands provide smooth and precise movements.

About 200 of these hands are used, mostly by researchers in universities and technology companies.

Walker said: "This is essentially a development toolkit for motor skills. You get this device, explore what can be done in terms of dexterity, and then it helps you determine what you want to build if you are going to create a larger system, or a bigger project, or deploy something."

This type of development is crucial for robots to interact with the human world, as most tools and devices are designed to fit the human hand.

Bryn Pears, founder of the robotics startup Kinesis located in Bristol, said: "I think the hand is the hardest and most complex part of any human-like robot."

Ten of the company's "KR1" robots are undergoing trials in commercial environments. They can be equipped with different grippers, depending on the task required from the robot. Strong grippers are used for picking up heavy boxes, or a suction device can be used for more sensitive items.

However, like most people in this field, Pears aims to provide a single hand flexible enough to perform all tasks.

A distant dream

Pears said: "For over 40 years, everyone has dreamed of a single mechanical hand that controls the world. Many believe that a human-like hand might be the solution." His company has built a hand with three fingers, which he describes as "very good."

He added: "But now the issue lies in how to make it strong, how to manufacture it on a large scale, and how to produce it at a reasonable price."

The cost of the initial hand model at Kinesis was about 4,000 British pounds (5,400 dollars), ten times the cost of the simple gripper the company currently uses, which is priced at just 400 British pounds.

Elon Musk, CEO of Tesla, emphasized the difficulty of developing a robust, adept, and affordable hand during his speech at the "All In" summit in Los Angeles in September last year.

Musk identified hand design as one of the three hardest problems facing manufacturers of humanoid robots. The other two projects were developing artificial intelligence that enables the robot to understand the world and mass-producing robots.

Musk promised that Tesla's humanoid robot Optimus would have "manual skills that match humans, i.e., a highly complex hand."

Nathan Lebora, a professor of robotics and artificial intelligence at the University of Bristol, said: "(This) is nonsense." Lebora has spent his career developing robotic hands and affirms that achieving the level of human skill is still out of reach.

He added: "It won't happen in two years, but we might be talking about 10 years until it happens, and this is still a relatively short period of time."

Lebora is currently working on a robotics project as part of the British government's ARYA research and development program. As with the "Shadow Robot" hand, Lebora is working on hands equipped with "tendons" that move the fingers.

He said: "In the long term, I think that hands that use tendons and more complex mechanisms will lead to more capable and affordable hands."

However, he expressed admiration for the progress made by Chinese companies that use motors in the fingers and hands to move them, instead of tendons.

Advancement by Chinese Companies

"Wuji Technology," based in Shanghai, is one of these companies. Each finger in its latest artificial hand contains four independently controlled joints, allowing for precise movements.

Yunzhi Pan, co-founder of "Wuji," says the hand is also durable, adding, "We will work on making it more durable in the next generation."

Each hand is currently sold at a price of 12,000 dollars, but Pan said: "We will work on reducing its price in the future."

Wuji's hand contains piezoelectric sensors that convert pressure into an electrical charge, providing a sense of touch.

Providing robots with a strong sense of touch would be a major achievement in the field of humanoid robots. But this is another area that needs a lot of work, Pears says.